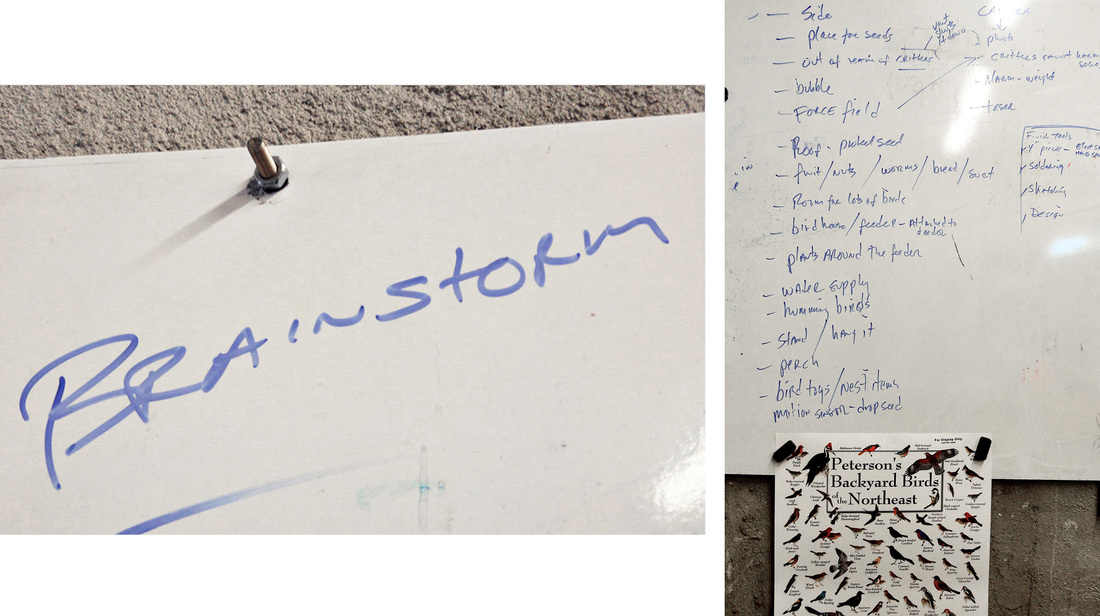

During our first week, the concept for the Bird Feeder Project was introduced. We spent time brainstorming ideas to incorporate in our feeder designs. The project called for the use of wood and metal in the design, but other materials can also be employed.

We spent time brainstorming ideas to incorporate in our feeder designs. The project called for the use of wood and metal in the design, but other materials can also be employed.

WEEK 2

Now, in Week 2, work on the bird feeders began in earnest.

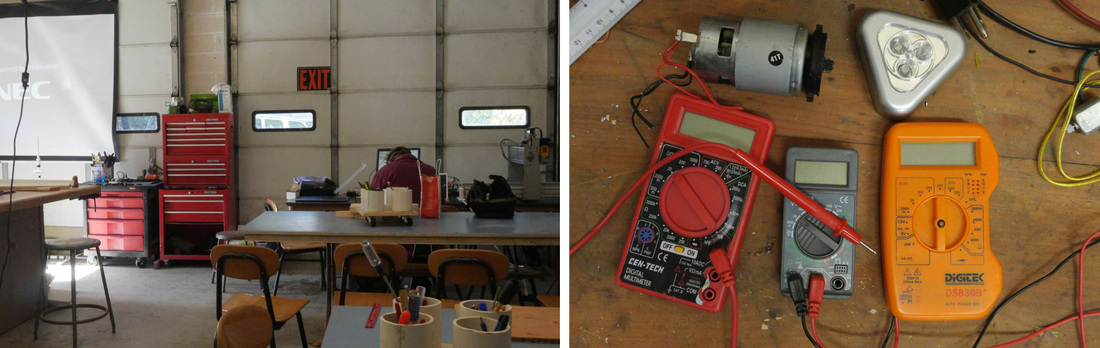

The first step was a review discussion of desirable design features. The mentors set up a table displaying materials other than wood and metal that that could be used: PVC pipe, wire mesh, flexible tubing, roofing shingles, and plastics.

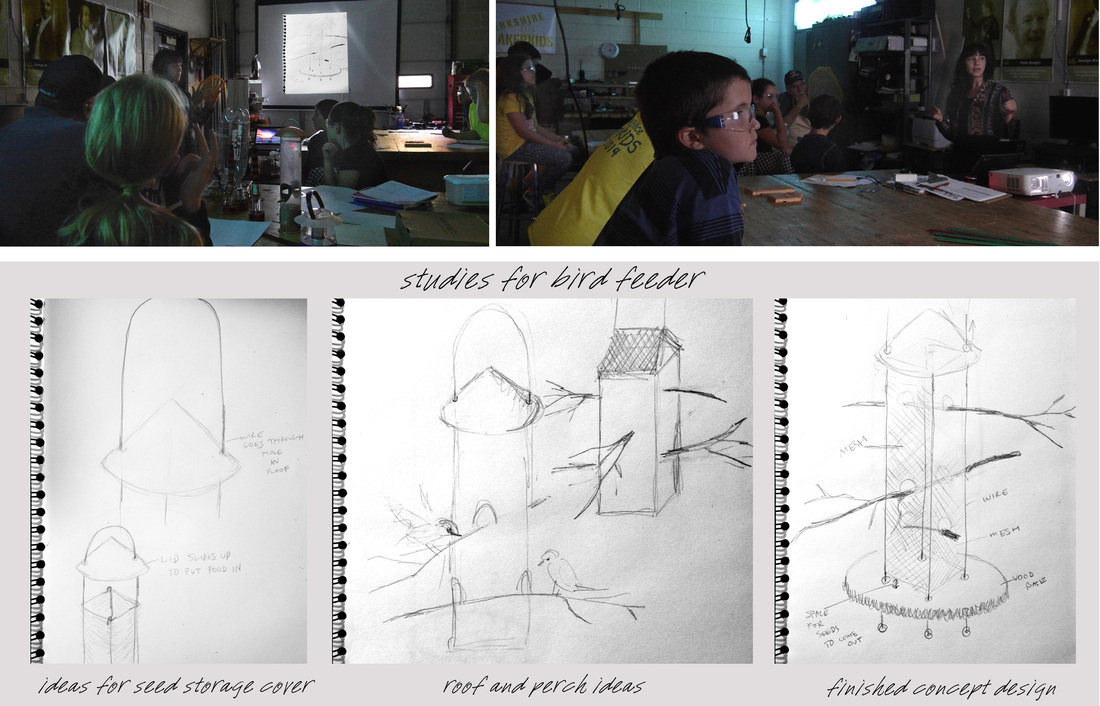

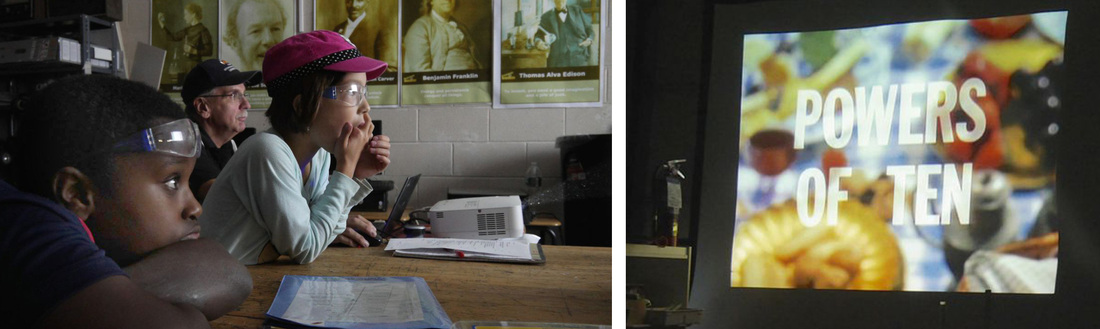

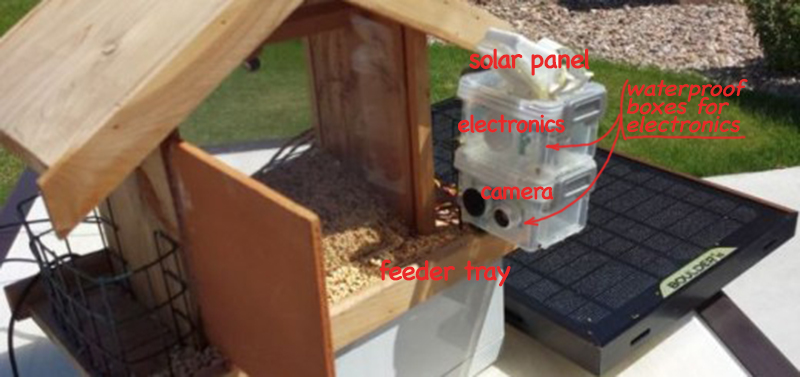

We showed some images of a design one of the mentors worked up in sketch for. The purpose was to get the MakerKids thinking about the design process, not to copy the design itself.

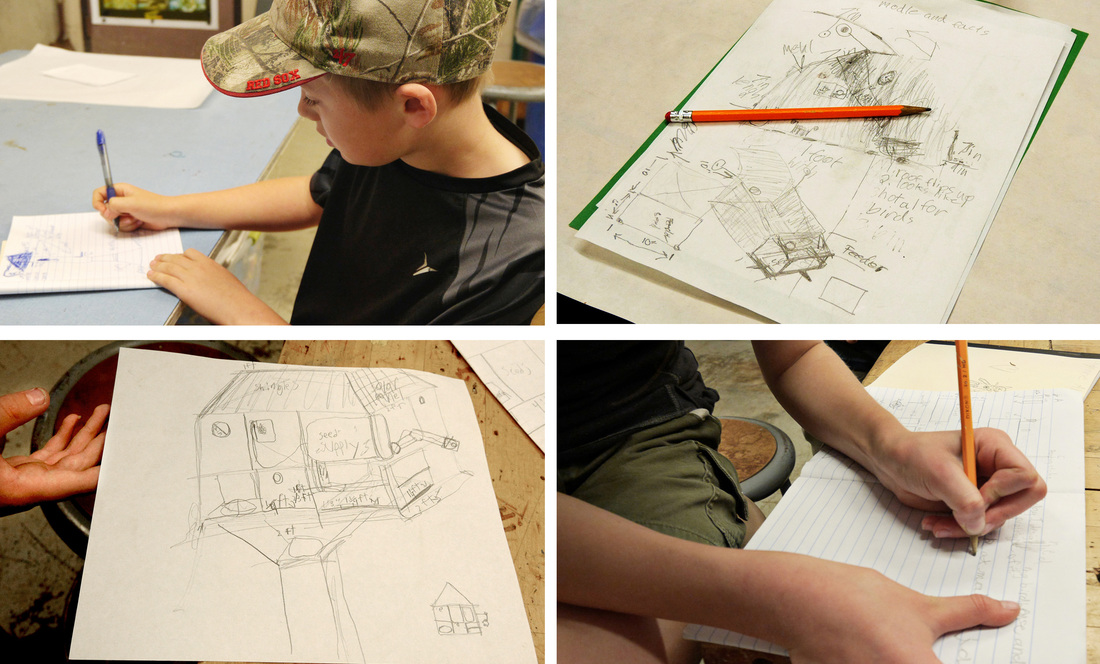

Then the MakerKids began sketching their ideas. Once the sketches seemed to be working, it was time to begin creating paper prototypes.

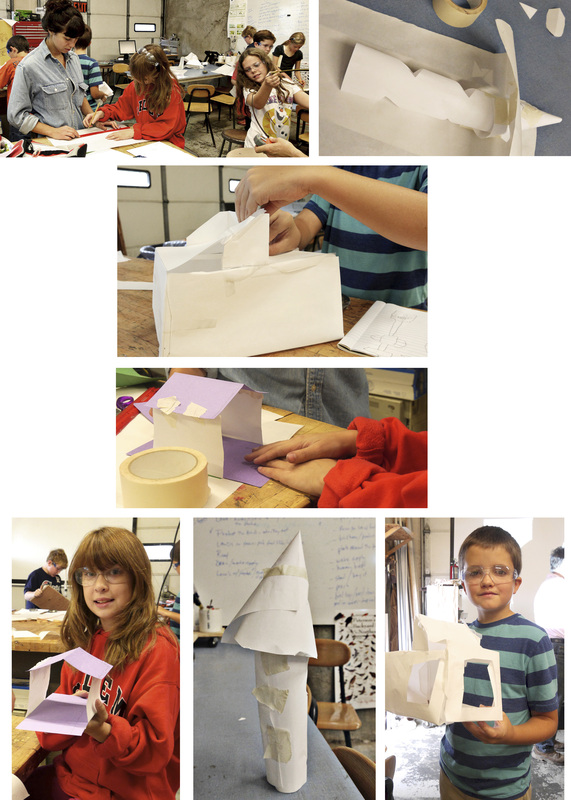

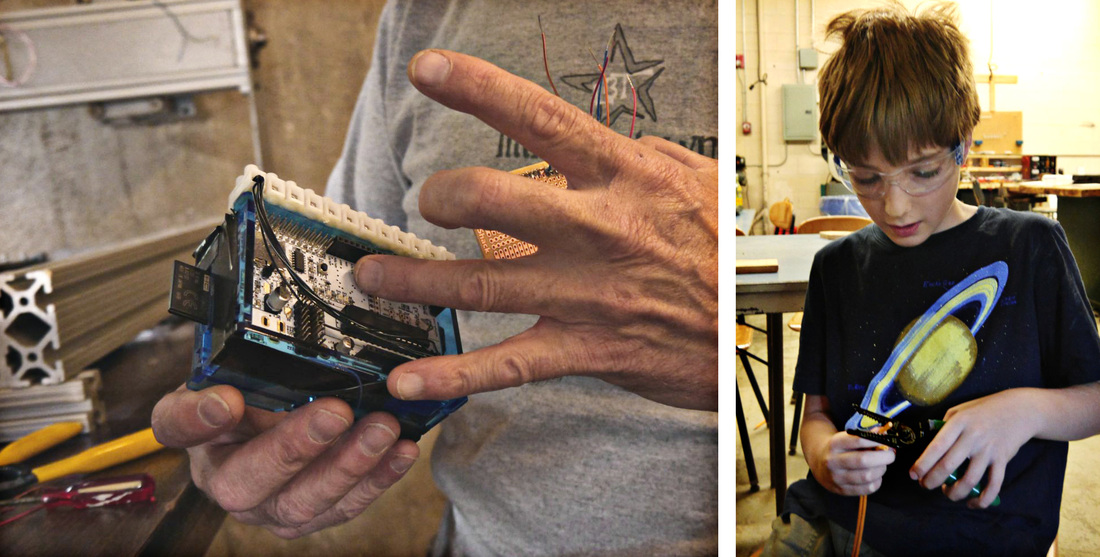

Prototyping allows us to clearly visualize the scale and overall shape of the finished design. It’s an important step in the design process that allows us to actually see the design in three dimensions without spending significant construction time or using costly materials.

Going directly from rough concept sketch of a bird feeder to a finished product made from wood and metal is too big a leap and usually results in a finished product that could have been better with more thought and planning. The use of prototyping will be a regular step in our design development process.

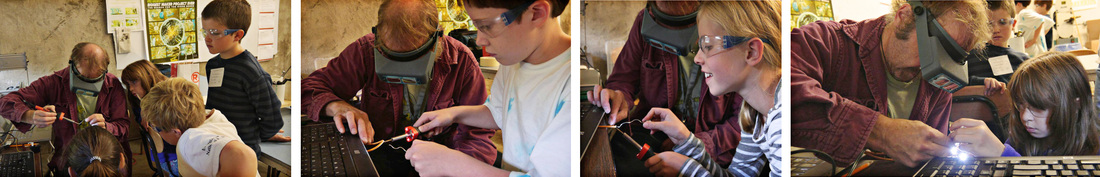

Each MakerKids completed a paper prototype and then discussed their overall design ideas and choice of materials with the mentor team.

Then, it was time to transfer the dimensions from the prototype to the materials that would be part of the finished feeder to be used as the base, walls, roof, perches, seed storage area and so on.

Cutting of wood and metal components was done by the MakerKids with close supervision by the mentors. In some cases, cutting required the use of an electric jig saw which was done by a

mentor.

mentor.

As our Week 2 sessions came to a close, many MakerKids had most or all of the pieces needed to assemble their bird feeders cut out and ready to put together.

MakerKids writing in their journals. Many are making lists of what they will need to do when they return next week.

MakerKids writing in their journals. Many are making lists of what they will need to do when they return next week. As is our practice, each session ends with the MakerKids spending time writing in their journals.

RSS Feed

RSS Feed